Prototyping and Testing

Design Review

The design and prototyping process for creating accessible door accessories has primarily been testing existing models found online and interviewing some users in one of our target demographics to understand their likes and dislikes of the existing solutions.

In our interviews, we received many pieces of feedback, positive and negative, all helping us refine our idea. One of our primary takeaways from these interviews was that users did not want to have something that needs to be put on and taken off every time they want to open the door, however, having something portable would be nice in situations where the door knobs are sticky and the doors are heavy.

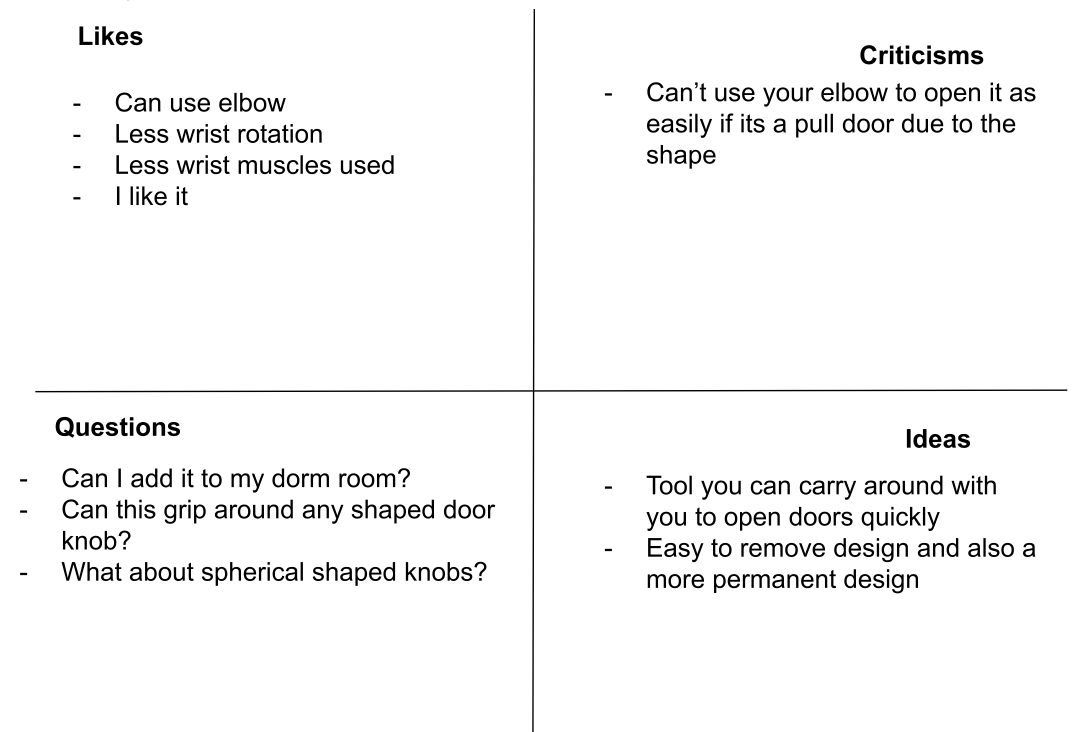

Another takeaway from this process was that being able to open a door with your elbow is very useful, not just for those with mobility issues, but also if your hands are full, being able to use your elbow to open a door is very useful. From this piece of feedback, we decided to make sure the handle would stick out far enough to ensure a person would be able to put sufficient pulling force on the door to turn the handle and open the door.

Not all of the feedback was positive though, in one of our interviews, we received the feedback that the handle did not feel secure on the door. This one is particularly important, as the handle needs to be able to secure to all kinds of door knobs while still being easily removable when necessary.

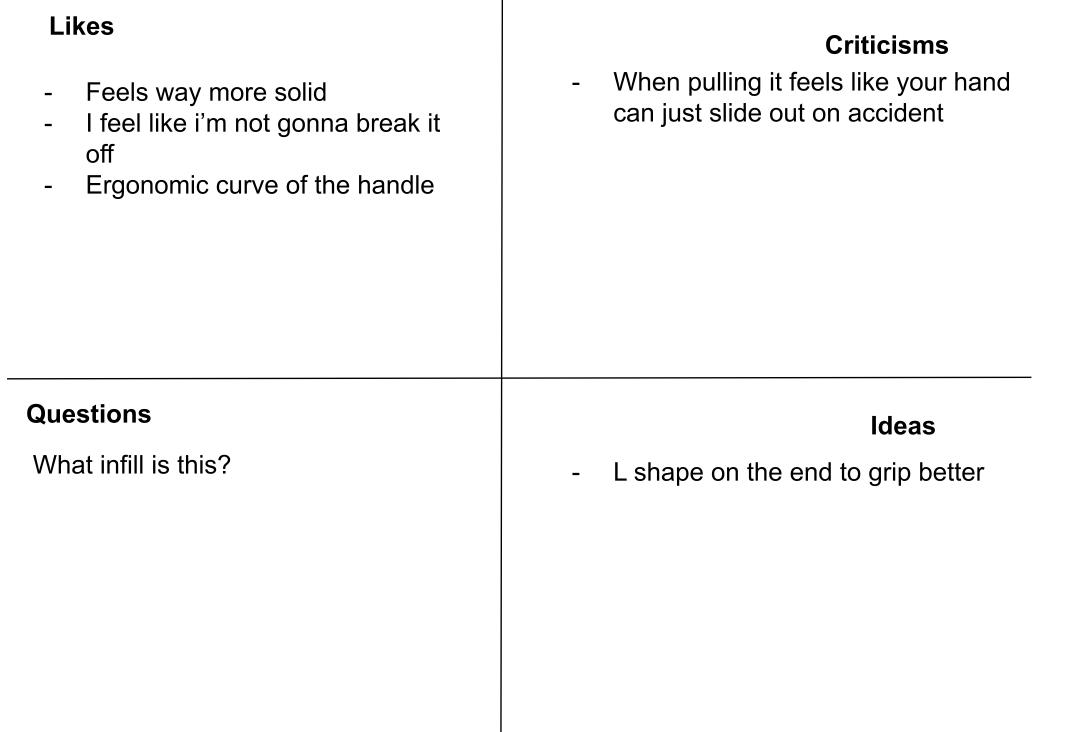

Another comment about the stability of the handle was less about the securing method to the door, and more about feeling secure when grabbing the handle to open the door. It was suggested that we add a curve to the end of the handle, making an almost L shape to ensure a hand cannot slide out of the handle while twisting it. This L shape would also provide more stability when opening the door with an elbow, as it would provide a bumper in that situation as well. Overall, the feedback we received was very helpful in furthering our design and our understanding of our problem at hand.

From this feedback, we gleaned several main guiding principles. From our understanding, our users want a handle that can be easily operated, even by one’s elbows. Another is that we need to make a design that stays on the door securely, while simultaneously being non-permanent. Additionally, one of our principles going forward is to make a universal design that works on (nearly) any door knob and only uses 3-D printed parts and common hardware. Lastly, we want to make sure to utilize a design that is easy for our team to iterate on throughout the design process.

Old “How Might We” Statements

- How might we adapt a design for multiple types of doorknobs?

- How might we combine the idea of a foot operated door with an adapted door knob?

- How might we weigh accessibility of materials with durability and performance?

- How might we work with DCL to ensure our solution complies with their rules and safety regulations of the state?

New “How Might We” Statements

- How might we modify the design to better stay in place on multiple types of door knobs?

- How might we collaborate with the maker spaces on campus to ensure anyone on campus could easily use our open-source design to make their dorm more accessible?

- How might we work with DCL to create a more permanent option for dorms on campus?

- How might we improve the durability of our design to withstand prolonged use?

We made some changes to our How Might We statements while collecting and analyzing feedback on our initial prototype. We found that our initial design already fit several different door knob shapes, but a more pressing issue was that it could be easily pulled or pushed out of place.

We also decided that the durability of metal screws outweighed the concern of accessibility of materials, since most students at Brandeis who would possibly be 3D printing this design would already be in a maker space to do so. In this case, we would want to ensure that those spaces were stocked with the additional materials needed to assemble our door knob adapter.

Additionally, we still want to work with DCL to ensure that our design is safe and compliant with any rules and regulations. If possible, we want to make it an option to semi-permanently install this design in your dorm room! The last change we made was a shift towards durability. Whether by using a stronger material or modifying our original design to be more sturdy, we want to ensure that these adapters can be used for an extended period of time if required.

Ideate

- Rubber insert

- Grippy material

- Thermal molding to the door knob

- Additional screw in the handle

- Thicker design and higher % infill

- Adding a lip on one or both sides

- Groove in the center of the cuff

- Changing the shape to be hooked or like an L

- Printing in metal

- Drill into the pre-existing door knobs

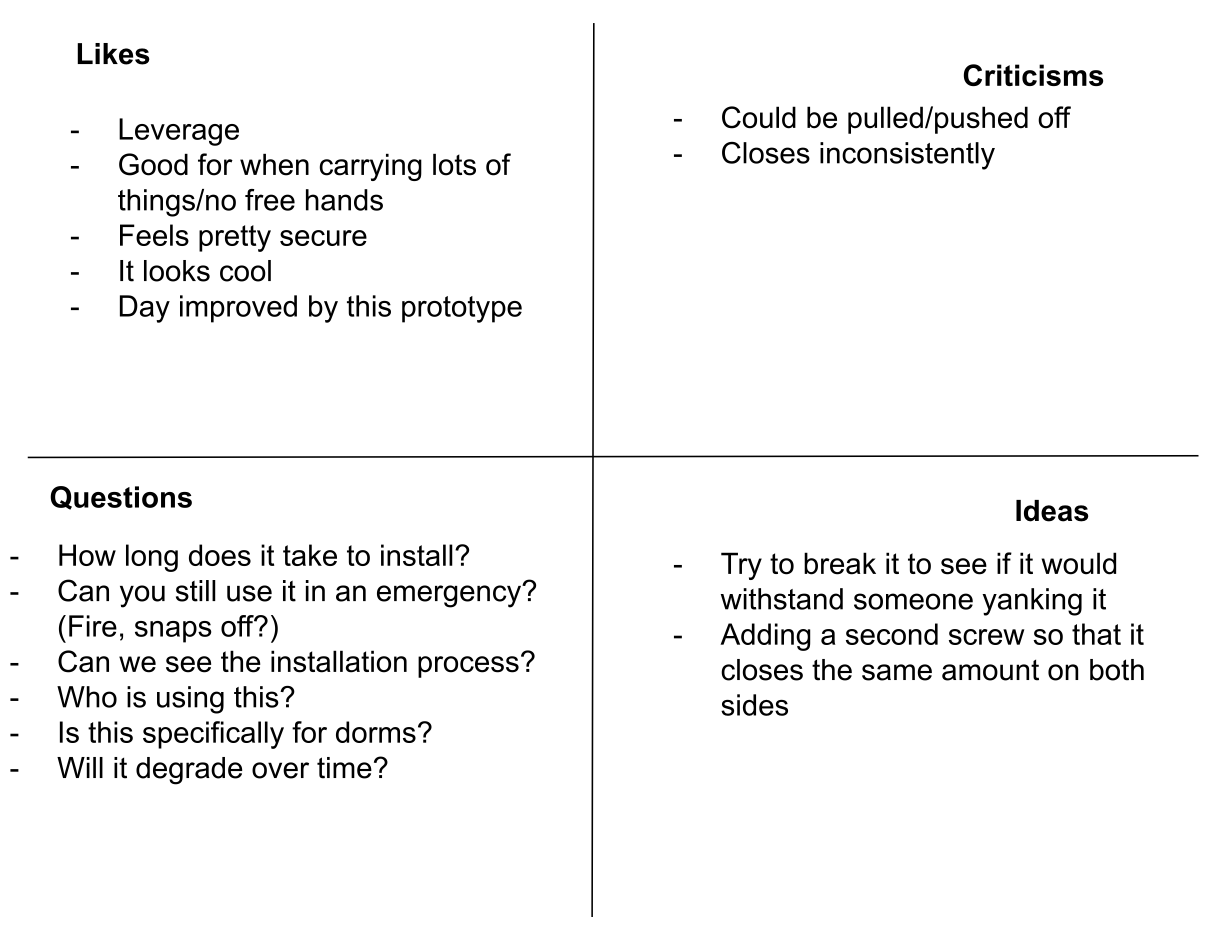

Feedback Grids

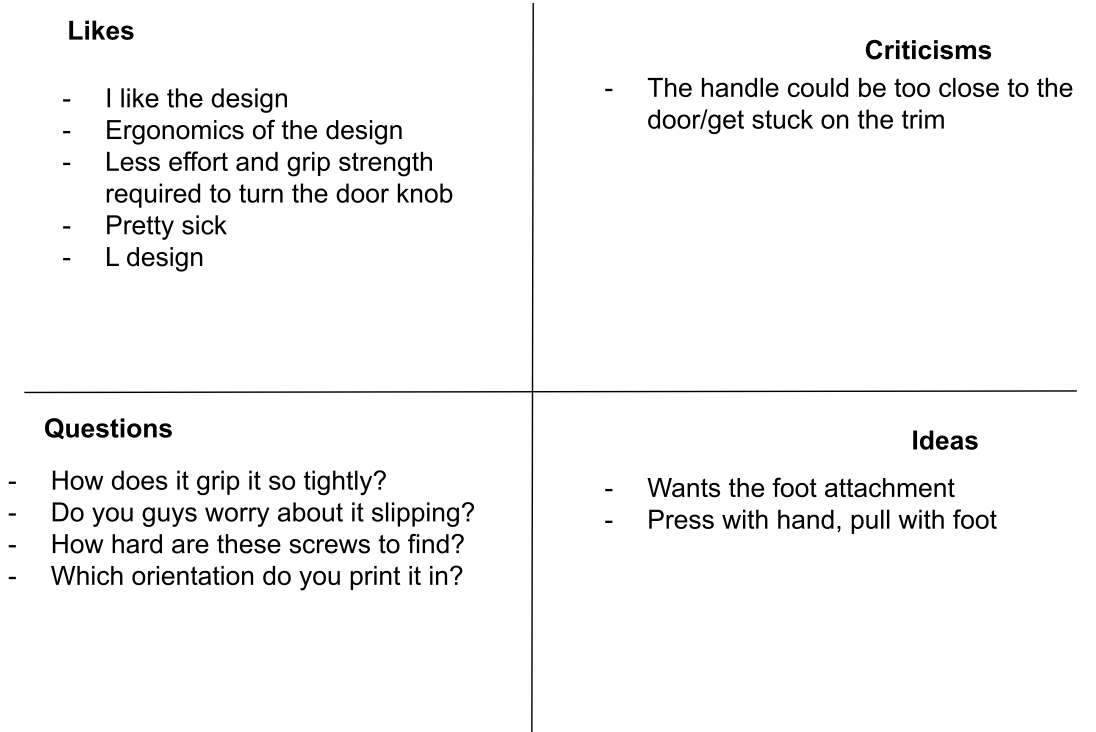

Group Grid

Interviewee 1 Grid

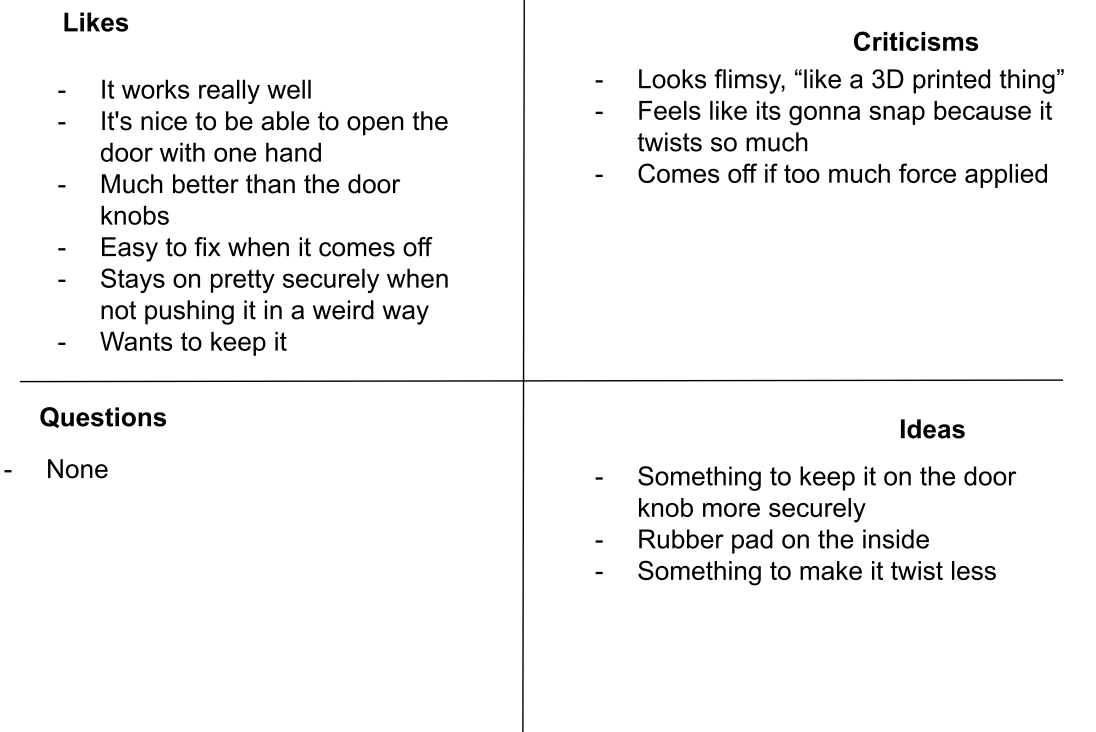

Interviewee 2 Grid

Interviewee 3 Grid

Interviewee 4 Grid

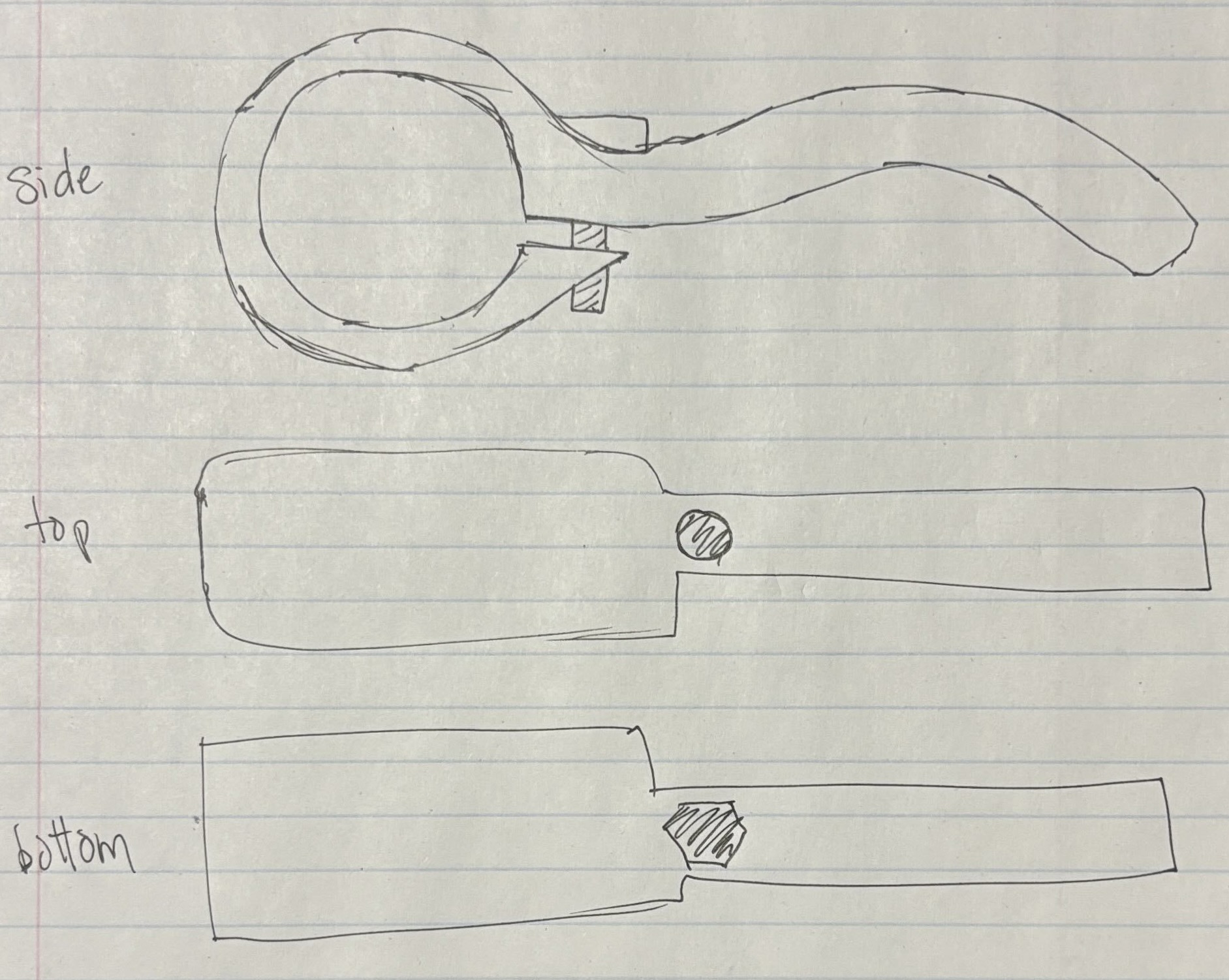

Sketch and Photos

About This Prototype

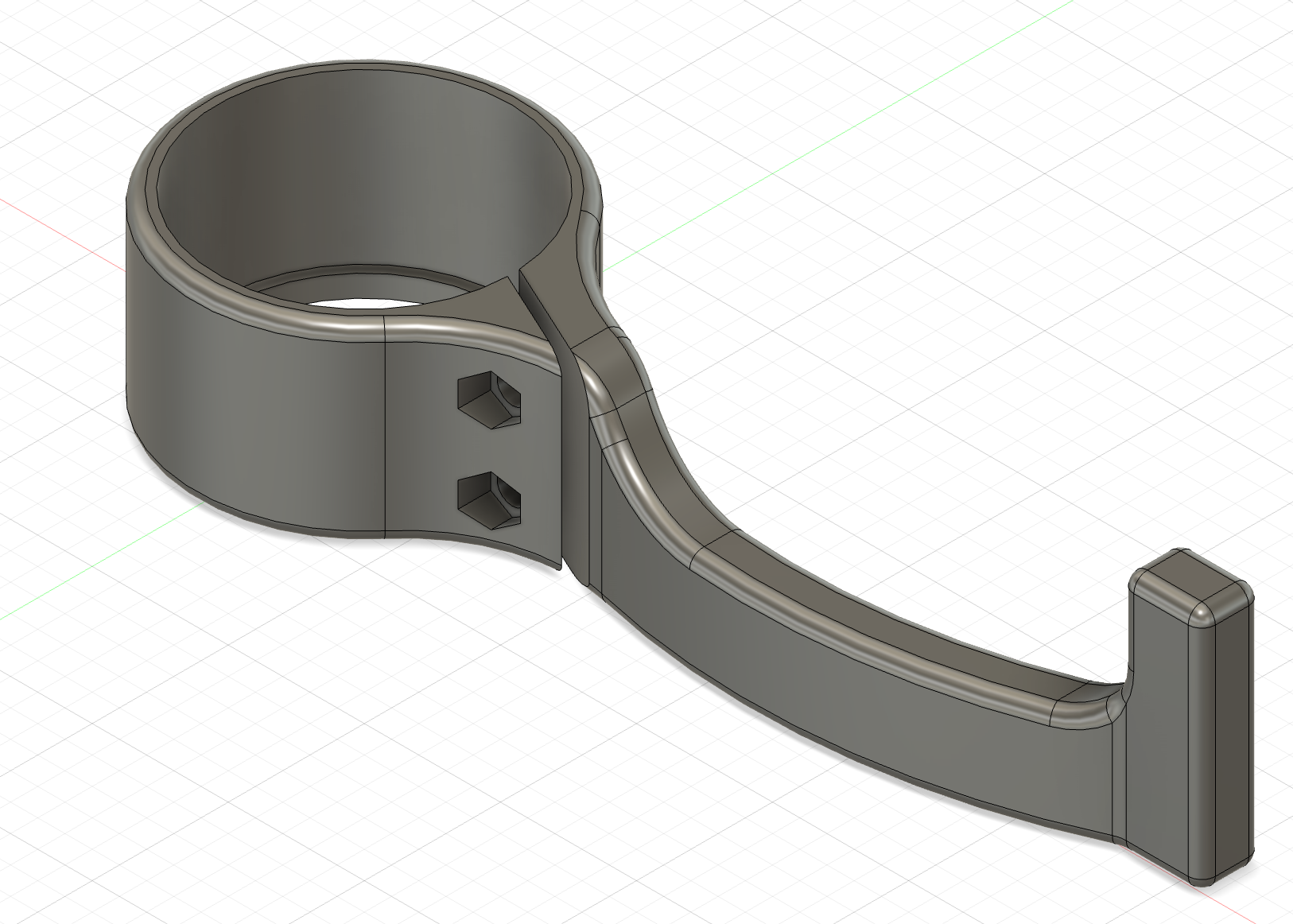

This prototype is our first iteration from the pre-existing model we found online. This iteration uses

the standard ~55mm diameter opening for the door knob to fit in with a modified 30mm height for the door

knob to hold on to. Originally, the amount of space for the plastic to interface with the door knob was less,

which resulted in lower rates of success when opening the door. As you can see in the image, the handle

does not go flush to the outer ring of the circular section, this proved to be a weak point, allowing for

too much flex when using the device, we have since fixed this issue with the next version of our prototype

seen in the image below. In addition, we have added an angle to the end of the handle as mentioned in the

analysis of the design review as well as a second screw to minimize flex.

Next Prototype